Optimizing Industrial Operations with Asset Performance Management Solutions

In the capital-intensive world of modern industry, the health and reliability of physical equipment are paramount to success. This is where the discipline of Asset Performance Management (APM) becomes a critical strategic imperative. APM is a comprehensive approach that leverages data capture, integration, and advanced analytics to improve the reliability and availability of physical assets. Its goal is to shift maintenance strategies from reactive to proactive, minimizing downtime and maximizing operational efficiency. As industries accelerate their digital transformation, the APM market size is projected to experience substantial growth, reaching an estimated USD 10 billion by 2035 and exhibiting a healthy compound annual growth rate (CAGR) of 7.82% during the 2025–2035 forecast period, highlighting its growing importance.

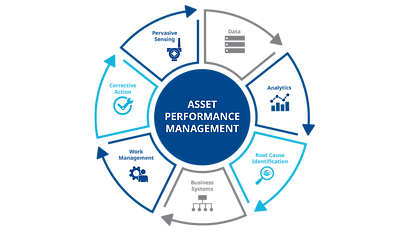

The core of any robust APM strategy is built upon several interconnected pillars that work together to provide a holistic view of asset health. The first is asset health monitoring, which involves collecting real-time data from sensors on equipment to track key performance indicators like vibration, temperature, and pressure. This data feeds into the second pillar: predictive maintenance (PdM). Using advanced analytics and machine learning algorithms, PdM can identify subtle patterns that indicate an impending failure, allowing maintenance to be scheduled precisely when needed. The third pillar, Reliability-Centered Maintenance (RCM), provides a strategic framework for analyzing failure modes and developing the most cost-effective maintenance strategy for each critical asset, ensuring that resources are focused where they will have the greatest impact on overall operational reliability.

Fueling these capabilities is a suite of powerful modern technologies that form the backbone of APM platforms. The Industrial Internet of Things (IIoT) is the foundational layer, with inexpensive sensors and wireless connectivity making it possible to collect vast amounts of data from previously unmonitored assets. This big data is then processed by sophisticated analytics engines, where Artificial Intelligence (AI) and Machine Learning (ML) algorithms uncover hidden patterns and predict future outcomes. A key enabling technology is the digital twin, a virtual replica of a physical asset that is continuously updated with real-time data. This digital model allows engineers to simulate performance, test maintenance strategies, and optimize operations in a risk-free virtual environment before applying changes to the real-world asset.

The benefits of implementing a comprehensive APM program are profound and far-reaching, delivering a clear return on investment. The most immediate impact is a significant reduction in unplanned downtime, which is a major source of lost revenue and production inefficiency in any industrial operation. By moving to a predictive model, maintenance costs are also drastically reduced, as work is performed only when necessary, eliminating the waste associated with routine, time-based maintenance schedules. Furthermore, by ensuring that equipment is operating within its optimal parameters, APM helps to extend the useful lifespan of critical assets, deferring major capital expenditures. Finally, in high-risk industries like oil and gas or power generation, improved asset reliability directly translates to enhanced operational safety and better environmental compliance.

Explore Our Latest Trending Reports:

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness